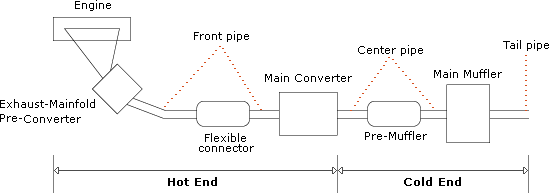

Automotive use

Reduce vibration from the engine to the exhaust pipe and provide noise reduction

Thermal expansion of exhaust pipe caused by absorbing high-temperature exhaust gas

Compensate for displacement of exhaust pipes, protect catalyst converters and gas

emissionsReducing air pollution has played a sealing role.

Before the product is shipped out, in order to provide customers with satisfactory and qualified products, the following tests need to be conducted:

Passenger cars, buses, trucks

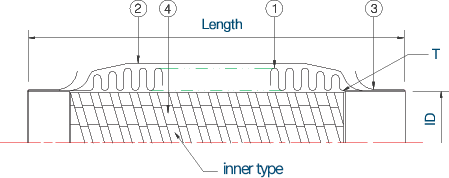

| MODEL | I.D.(mm) | t | basic ply | LENGTH(mm) | inner type | notes |

|---|---|---|---|---|---|---|

| JFT-43 | 43.2A | 0.2 ~ 0.4 | 2 | 80 ~ 280 | In/Braid OR Inter Lock | For passenger cars |

| JFT-45 | 44.9A | 0.2 ~ 0.4 | 2 | 80 ~ 300 | In/Braid OR Inter Lock | " |

| JFT-49 | 49.5A | 0.2 ~ 0.5 | 2 | 80 ~ 320 | In/Braid OR Inter Lock | " |

| JFT-52 | 52.4A | 0.2 ~ 0.5 | 2 | 100 ~ 350 | In/Braid OR Inter Lock | " |

| JFT-54 | 54.5A | 0.2 ~ 0.5 | 2 | 100 ~ 400 | In/Braid OR Inter Lock | " |

| JFT-60 | 60.5A | 0.2 ~ 0.5 | 2 | 150 ~ 400 | In/Braid OR Inter Lock | " |

| JFT-70 | 70A | 0.25 ~ 0.5 | 2 | 200 ~ 450 | Bellows +Pipe welding | For commercial vehicles |

| JFT-90 | 90A | 0.25 ~ 0.5 | 2 | 200 ~ 450 | Bellows +Pipe welding | " |

| JFT-101 | 101A | 0.25 ~ 0.5 | 2 | 200 ~ 450 | Bellows +Pipe welding | " |

| JFT-103 | 103A | 0.25 ~ 0.5 | 2 | 200 ~ 450 | Bellows +Pipe welding | " |

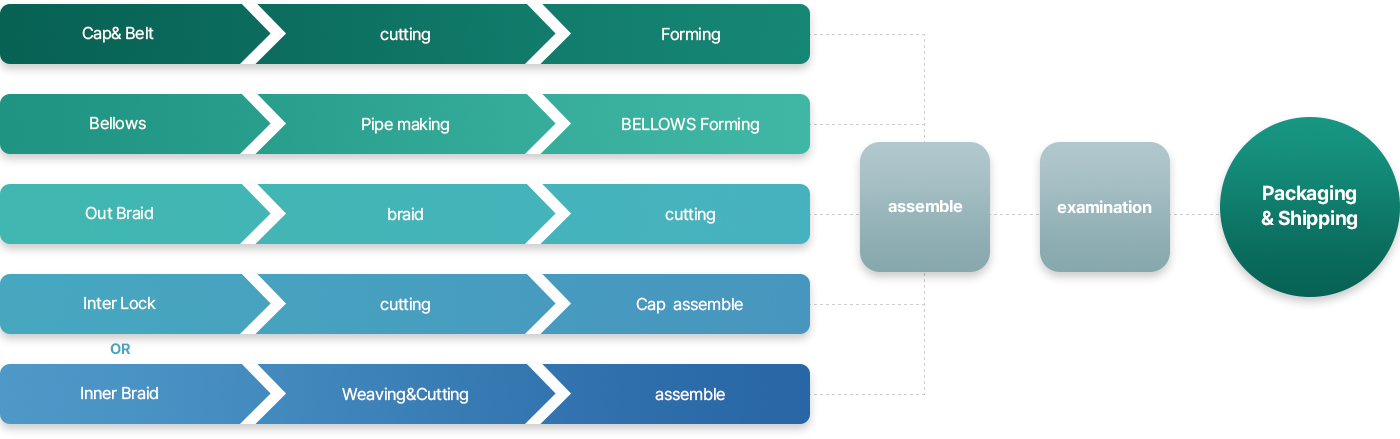

| Part Name | material | Specifications | QT'Y | notes |

|---|---|---|---|---|

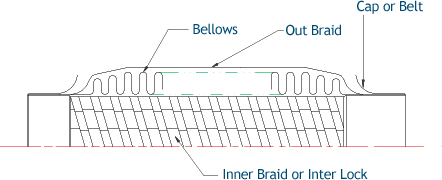

| Bellows | STS 304, 321, 310S, XM15J1, NAR315SN, ER-1, ER-4외 | 2PL | 1 | The material can be customized according to customer requirements |

| Out Braid | STS 304W, 316Ti, XM 15J1외 | Ø0.4 | 1 | External network sleeve specifications: 9 x 64 or 12 x 48 |

| Cap or Belt | SACE80/80, STS 409L, 430PL외 | 1.2t | 2 | |

| Inner Braid or Inter Lock | STS 304W외 | Ø0.4 | 1 | Internal network sleeve specifications: 7 x 64 or 9 x 48 |

| STS 304W, SM15J1, DIN1.4828외 | 0.3t |

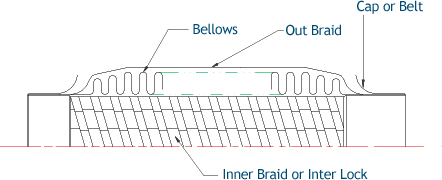

| 부품명 | 역할 |

|---|---|

| Bellows | Provide primary elastic support to prevent exhaust gas from flowing out and absorb vibrations |

| Out Braid | Provide external protection, strengthen the welding strength between corrugated pipes and exhaust pipes, and prevent external damage |

| Cap or Belt | Prevent excessive deformation, strengthen the welding strength between corrugated pipes and exhaust pipes, and prevent external damage |

| Inner Braid or Inter Lock | 배기가스로부터 Bellows 보호, 소음감쇄 |